The rise of plastic waste is an issue that continues to affect the environment, with polyethylene (PE) films being a significant contributor. PE films are commonly used in various industries for packaging, and these films come in different forms, including low-density polyethylene (LDPE) and high-density polyethylene (HDPE). Given their widespread use, developing effective recycling methods is essential for reducing environmental impact. Mixed PE film recycling, in particular, has become a specialized process that addresses the unique challenges of handling blended polyethylene materials. In this article, we’ll explore what mixed PE film recycling entails, its benefits, and the technologies that support this eco-friendly initiative.

Understanding Mixed PE Films

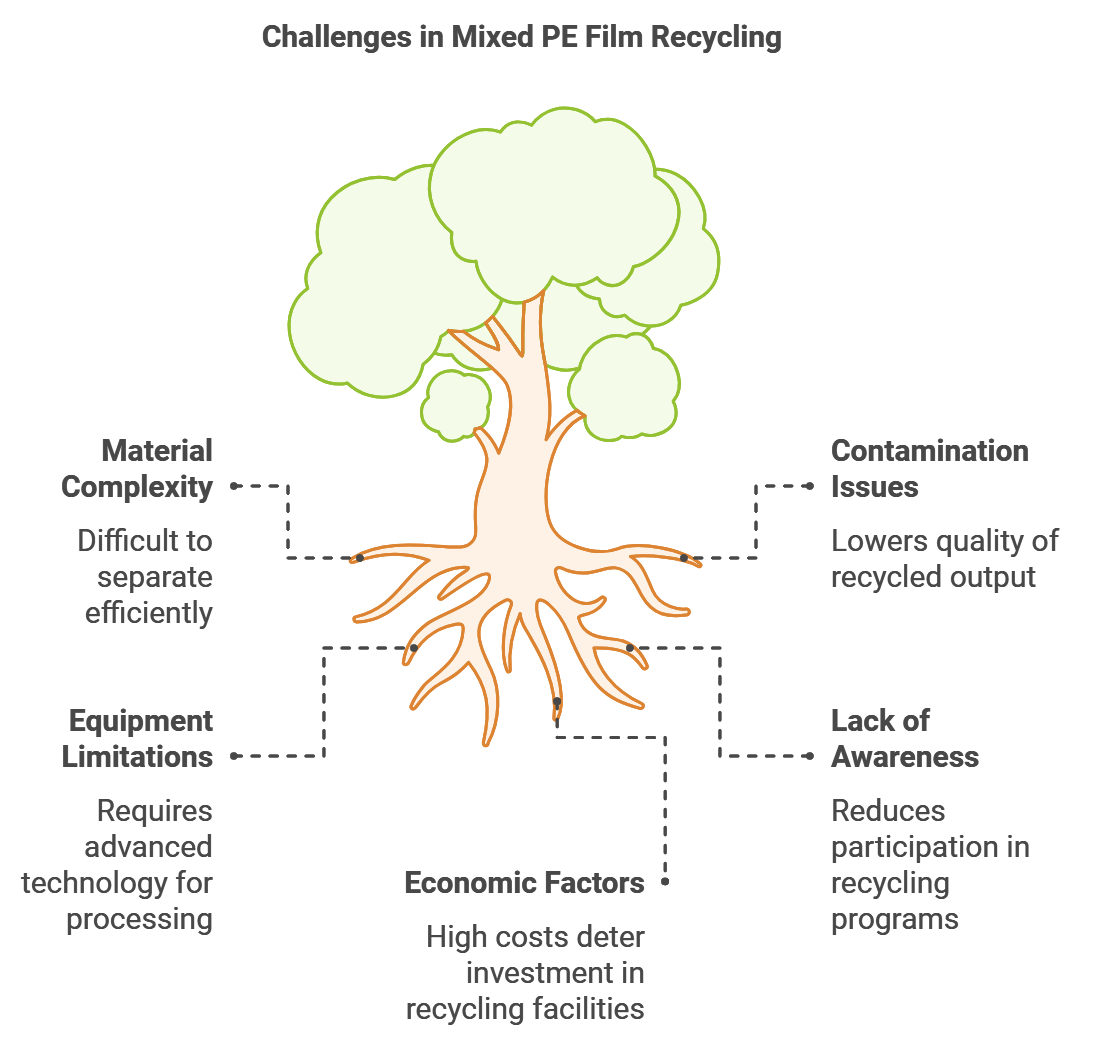

Mixed PE films typically include a combination of LDPE, HDPE, and sometimes linear low-density polyethylene (LLDPE). These films are widely used in packaging, agriculture, and consumer products, contributing to the vast amount of plastic waste generated each year. However, recycling mixed PE films is challenging due to the differences in material properties, such as density, melting points, and flexibility. This makes separating and processing them efficiently a complex task that requires advanced equipment and specialized knowledge.

Benefits of Mixed PE Film Recycling

Recycling mixed PE films provides numerous environmental and economic advantages:

1. Reduction in Landfill Waste: Recycling mixed PE films prevents these materials from ending up in landfills, where they would otherwise take hundreds of years to break down. By diverting plastic waste from landfills, we reduce environmental pollution and make better use of resources.

2. Resource Conservation: PE film recycling conserves valuable raw materials and energy that would otherwise be required to produce new plastic. By recycling, manufacturers can obtain high-quality secondary raw materials that reduce the demand for virgin plastic, ultimately lowering the carbon footprint.

3. Cost-Effectiveness for Businesses: Recycling processes that recover usable material can help businesses save on waste disposal costs and even generate revenue from the recycled plastics. This is particularly beneficial for industries that produce large quantities of polyethylene waste, such as packaging and agriculture.

How Mixed PE Film Recycling Works

To recycle mixed PE films, specialized machines are used to optimize the recycling process. These machines go through several key stages, each of which is crucial for producing high-quality recycled material.

1. Collection and Sorting

The process begins with the collection of mixed PE films, which may come from post-consumer or industrial waste sources. Proper sorting is essential to separate contaminant-free PE films from materials containing other types of plastic or impurities. Automated sorting technologies, such as infrared detection, can help identify and separate materials based on density and chemical composition, ensuring cleaner and more efficient recycling.

2. Washing and Drying

Once sorted, the PE films undergo thorough washing to remove dirt, labels, and adhesives. Washing is critical for producing high-quality recycled pellets, as contaminants can lower the quality of the final product. After washing, the materials are dried to prepare them for the next steps in the recycling process.

3. Shredding and Pelletizing

The cleaned films are then shredded into smaller pieces, which makes them easier to melt and reform. Shredding machines are designed to handle the soft, flexible nature of PE films without causing blockages. The shredded pieces are then melted and extruded into pellets, which can be used as raw material for producing new plastic products.

4. Quality Control

Before the recycled pellets are ready for sale or reuse, they undergo rigorous quality control to ensure that they meet industry standards. This includes checking for purity, strength, and consistency, as these factors directly affect the usability of the recycled material in manufacturing new products.

Technologies for Optimized Mixed PE Film Recycling

With advances in recycling technology, new machines have been developed to handle the specific demands of mixed PE film recycling. High-efficiency extruders, for instance, allow for precise control over temperature and pressure, ensuring that different PE types melt uniformly without compromising quality. Furthermore, machines equipped with sensors and automated controls can adjust to different materials, reducing downtime and increasing overall productivity.

Some of the innovative technologies used in mixed PE film recycling include:

Infrared Sorting Technology: For accurately identifying and separating different types of polyethylene.

High-Speed Washers: To remove impurities more effectively, enhancing the quality of recycled material.

Specialized Extruders: Designed to process the unique properties of mixed PE films, ensuring high-quality pellet production.

Final Thoughts

Mixed PE film recycling is a powerful solution for reducing plastic waste and conserving resources. By using specialized machines and optimizing recycling processes, manufacturers can achieve high-quality recycled material suitable for creating new products. Not only does this support a more sustainable economy, but it also provides businesses with cost savings and opportunities to minimize their environmental impact.

As recycling technologies continue to evolve, mixed PE film recycling is likely to become even more efficient and accessible, paving the way for a greener, more sustainable future. If you’re looking to reduce waste and improve sustainability, consider investing in or partnering with facilities that specialize in mixed PE film recycling. Together, we can make a lasting impact on the environment—one recycled film at a time.

Post time: Nov-08-2024